HAMMERLI 160

Sight Adjustments

Clockwise down.

Clockwise right.

1 click = 10mm @ 50m.

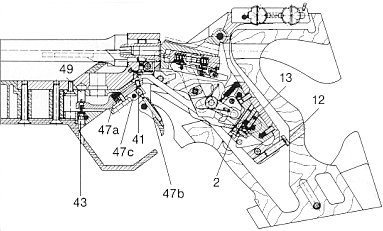

Trigger Adjustments

Trigger Weight: This is increased by turning screw 43 (2.5mm allen key)  clockwise. 1 turn = 15 grams.

clockwise. 1 turn = 15 grams.

If a trigger weight of 30 grams or less is required:

1. Turn screw 43 anticlockwise to its stop.

2. Remove grips.

3. Turn screw 2 anticlockwise (1 turn = 4 grams).

Caution: At trigger weights of less than 30 grams the slightest impact is enough to set the gun off. Lowest possible setting is 10 grams.

Sear Engagement

Initial setup: (This should only ever be necessary if the trigger unit has been dismantled)

1. Remove grips.

2. Set the trigger. Slowly turn sear engagement screw (13) clockwise with 1.5mm allen key until the sear releases.

3. Turn screw back one half turn anticlockwise.

Normal Setup:

1. Set trigger.

2. Turn screw 49 (1.5mm allen key) slowly anticlockwise until the sear releases.

3. Turn screw clockwise at least one eighth of a turn.

Grip Angle

There is an adjustment of up to ten degrees of grip rake angle. Loosen grip screws and position grip to desired angle. Then unscrew bolt 12 through hole in rear of grip until it butts against the inside of the grip. In this way the angle will ne maintained each time the grips are removed and replaced.

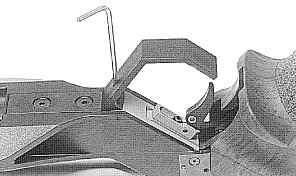

Stripping

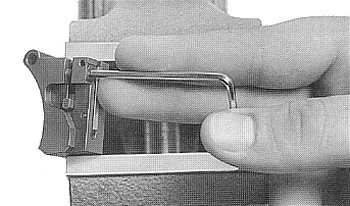

| Check pistol is unloaded. Remove grips. Slacken grip screws (both sides), pull away grips down and to the rear. Remove breechblock. This must be cocked when removed and replaced in the receiver. Slacken and remove bearing screw and nut (as illustrated). The cocked breecjblock can be removed by lightly moving the breechblock lever and tipping the pistol. |

|

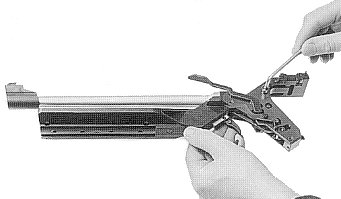

| To change the firing pin. Slacken off pressure on firing pin by pushing up retention catch. CAUTION. Use a drift to knock out rear pin by 2mm. Remove retention catch and compression spring. Clamp breech block in a vise in such a manner that the spring washer can be pressed in easily. This takes away pressure from the countersunk allen screw and it can be then removed. Remove spring washer, firing pin spring and firing pin. |

|

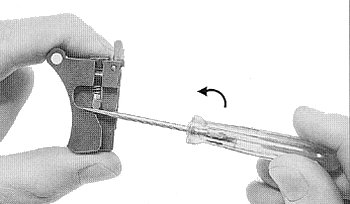

| Assembly proceeds in reverse order. Before the breechblock can be inserted, the firing pin must first be cocked (as illustrated). |  |