SIG-HAMMERLI P240

Sight Adjustments

Clockwise down.

Clockwise right.

1 click = 10mm @ 25m

Trigger Adjustments

Trigger Weight

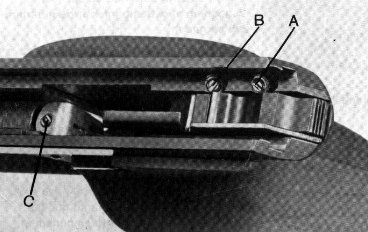

Turn Screw A clockwise to increase trigger weight. Approx. 180 degrees to increase from 1000 to 1360g.

Take-up Weight

This adjustment principally only for adjustment at the factory.

Turning Screw B clockwise will increase take-up weight.

Turning anti-clockwise reduces spring tension and can lead to malfunctions as the sear will no longer return from the final let-off engagement in the hammer-notch to the normal full engagement.

Trigger Bar Engagement

Do not touch this screw (C). If you do you will invoke the Curse of the Hammerli Tooth Fairy (she carries pliers!)

Sear Engagement

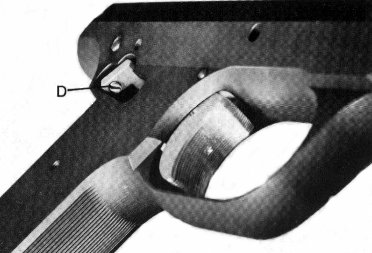

This screw (D) should only be adjusted in case of necessity due to changed engagement at the let-off point.

Turn clockwise to increase engagement.

Trigger Stop

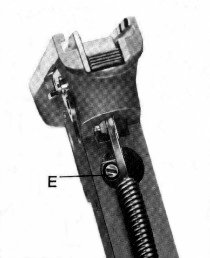

Turn Screw E clockwise to shorten backlash.

Note: If the backlash is adjusted too short the sear/hammer notches could be damaged, as the sear will not be pulled enough from the hammer notch.

Stripping (For .38 cal)

Check that pistol is unloaded, ease hammer forward and remove magazine.

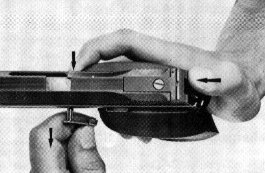

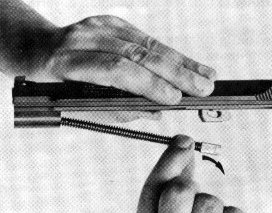

Hold pistol with the right hand as illustrated. Pull back the slide about 10mm and simultaneously insert takedown tool between slide front and recoil spring rod.

Push slide forward until its rear surface and the frame are even. Press breech lock  lever to the left and pull it out with the left hand. Remove takedown tool.

lever to the left and pull it out with the left hand. Remove takedown tool.

Withdraw slide/barrel/recoil-spring assembly to the front.

Grasp recoil spring rod at rear and extract by pulling it up and back.

Barrel may be removed in the same manner as the recoil spring rod.

Reassembly

Assembly procedure is in the reverse order but without the use of the takedown tool. The rear surface of the slide and the frame must be even before the breech lock lever can be pushed through the drilling in the frame, the locking-curve on the barrel and the slot in the recoil spring rod.

Stripping (.22 and .32 cal)

Check that pistol is unloaded, ease hammer forward and remove magazine.

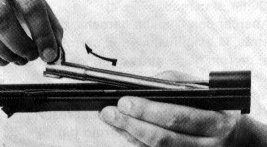

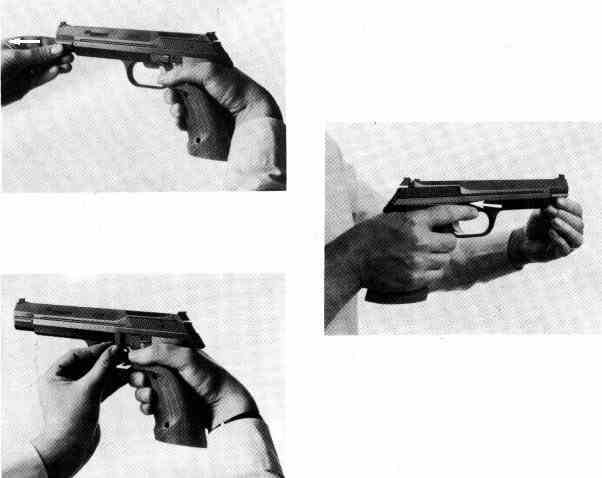

Pull the plastic dismantling grip of the slide slightly forward with the left hand, at the same time pushing the slide catch to the left with the right hand and completely remove it. Slide and barrel will now slide off the front of the frame.

Lay the slide with the barrel and the recoil spring down, so as to come to rest upside down on front and rear sight. Hold the system with the left hand by the grooved part of the slide and pull the dismantling grip forward with the right hand until the recoil spring rod comes out of the lateral guide slot, at the same time pulling in the opposite direction with the left hand and lifting the slide off.

The pistol has thus been dismantled sufficiently in order to be thoroughly cleaned.

Reassembly

To reassemble, proceed in reverse order. Before mounting the system, make sure that the recoil spring guide rod sits properly in the lateral guide slots. When putting the slide on the frame, ensure that the slide is pushed back until the rear edges of the frame and the slide are flush. Insert the slide catch only then.

Further Notes

From a Hammerli Tech Sheet dated December 1977

Magazine Followers for the 22 Conversion

It seems the first batch of 22 conversions released by the factory were prone to misfeeding.

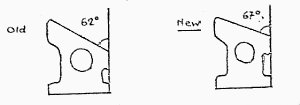

The diagram shows a modification to the plastic follower suggested by the factory to solve the problem. Instead of an angle of 62 degrees, which was original in early magazines, change that angle to 67 degrees. Parts are now very difficult to locate and the replacement parts are not likely to be available.

Bulged Barrels

Hammerli made a point of documenting the dangers of handloaded ammunition, and the possibility of bulging the barrel if a round is fired while there is ANY obstruction in the barrel.

There have, in fact, been many cases in Australia where P240s in 38 Spl have had bulged barrels. This is in part due to the slender profile of the barrel, but perhaps also due to the tightness of the bore adding to chamber pressures, which as a result makes skirt separation of hollow based wadcutters more likely. The next shot thereafter would cause the bulge.

Factory specs of the centerfire barrels were as follows:

| .38 Spl WC | .32 S&W Long WC | |

| Bore Diameter (Between the lands) |

8.70mm + 0.05mm (.3425″ +0.002″) |

7.75mm + 0.03mm (.3052″ + .001″) |

| Groove Diamater | 8.95mm + 0.05mm (.352 + .002″) |

7.92mm + 0.03mm (.3118″ + .001″) |

| Twist Rate | 1 in 500mm (1 in 19.7″) |

1 in 400mm (1 in 15.7″) |

Magazine Lips

The following are the correct dimensions for P240 magazine lips. Should your pistol not feed correctly, check these measurements and modify them if necessary.

| .38 Cal | .32 Cal | .22 Cal | |

| Distance between lips – front | 9.60mm (.378″) |

8.60mm (.338″) |

5.70mm (.224″) |

| Distance between lips – rear | 7.50mm (.295″) |

7.50mm (.295″) |

5.20mm (.204″) |