WALTHER GSP

Sight Adjustments

Clockwise down. This makes perfect sense when you realise that “bei” means “if”.

Clockwise left.

1 click = 7mm @ 25m for elevation.

1 click = 5mm @ 25m for windage.

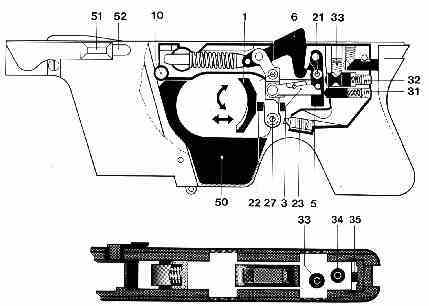

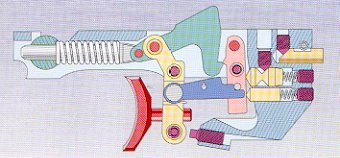

Trigger Adjustment (Late Model 2-Stage Trigger)

Basic Setting

The following are the factory instructions for a basic setup using the first stage travel adjustment screw.

Cock the hammer. If it does not engage, turn screw 21 anti-clockwise until the hammer engages. Now slowly turn screw 21 clockwise until the hammer is disengaged, then turn it anti-clockwise two turns.

If the trigger bar (3) does not engage in the sear (5) and if the hammer cannot be released, screw 22 must be turned anti-clockwise until the engagement of the trigger bar with the sear is audible. Reduce any play between trigger bar and sear by turning screw 22 clockwise.

Trigger Shoe Position

Loosen screw 27 to adjust length of pull and shoe angle. Left handed shooters should turn the shoe through 180 degrees.

Trigger Stop

Screw 23.

First Stage Weight

Screw 31. Clockwise to increase weight.

After adjustment check the play between trigger bar and sear, and adjust as necessary as in “Basic Setting” above.

Second Stage Weight

Screw 32. Clockwise to increase.

Sear Engagement

The sear engagement is reduced if screw 33 is turned clockwise. If 33 is screwed in too far, no second pressure will be felt.

Caution! If screw 33 is withdrawn too far, it no longer locates in the slot in the plunger of screw 32. To relocate this, remove screw 32 with spring and plunger, and realign the nib of 33 with the hole in the plunger and reassemble.

Stripping Instructions

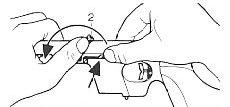

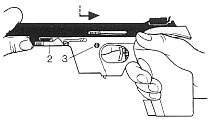

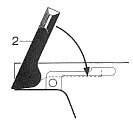

| Remove the magazine. Check pistol is unloaded. Let slide forward and uncock the pistol. Push the locking spring on the slide locking lever (2) in and turn the latter fully forward. |

|

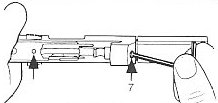

| Push the upper part (barrel with slide) forward by about 7mm and lift upward. The slide lock must lie horizontally. DO NOT USE FORCE. Caution: Do NOT put the upper down on its top side! |

|

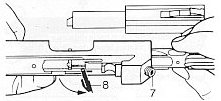

| Loosen the barrel locking screw (7) with the Allen key until the locking pin for the cocking piece (see arrow) coincides with the hole in the side casing. |  |

| First remove one cocking knob by loosening the Allen screw, then push the spring-loaded pin inward and tap the tight-fitting cocking knob out sideways. When inserting the cocking knob, the liner (a) must point to the rear. |  |

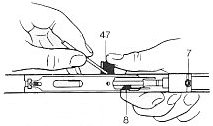

| Open the hinged ejector (8). Loosen the barrel locking screw (7) until the barrel can be withdrawn, then pull the breech block out of the slide casing. |  |

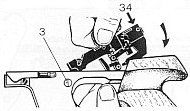

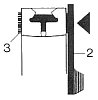

| Turn screw (34) anti clockwise, hold the trigger by the decocked hammer and remove it upwards by turning it around the locking pin. |  |

| To reassemble: Do not use force! Re-insert the breech block in the slide casing. Mount the barrel and with the barrel holding screw (7) down firmly, then push in the cocking grip (47) and turn the ejector back (8). Push the trigger unit firmly into the frame and lock with the locking pin (3). The point on the locking pin must then stand in line with the barrel. |

|

| Now place the slide casing on the frame at a spot about 7mm forward of the “closed” position, push fully backwards, then turn the slide locking lever (2) fully home to the rear. |  |

Readjusting Slide Locking Lever

The slide locking lever firmly connects the frame with the slide casing. If the clamping strength weakens, readjust the slide locking lever in the following manner:

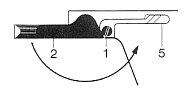

| Turn the slide locking lever (2) forward. Remove the screw (1) and lift the star spring (5) off and out. Screw the slide locking lever out by about two and a half turns. |  |

| Hold the nut (3) on the opposite side firmly in position while doing so. |  |

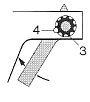

| Push the slide locking lever (2) against the pistol. This causes the nut (3) to be pushed clear of the locking pin (4) so the nut acn then be adjusted. To increase the tension, turn clockwise; to decrease, turn anti clockwise. |  |

| Push the nut (3) in again and turn the slide locking lever (2) back into the “locked” position. A certain amount of gripping pressure must be perceptible while the lever is being pushed home through the final portion of its travel. Check to ensure that the slide casing sits firmly on the frame, then replace screw (1) and spring (5). |

|